Plaza Deck Sytems for commercial Buildings

It’s hard to imagine any urban setting without parking garages. Giving the limited availability of usable areas in busy cities, parking structures efficiently provide stalls for vehicles in airports, train stations, bus stations, commercial buildings, hospitals, and malls. Those structures are commonly built using cast-in-place, precast concrete, post-tensioned concrete, structural steel, even engineered lumber, or a combination of these systems. Structural parking decks consist typically of reinforced concrete slabs over precast supporting units. Slabs’ initial slopes and their structural deflections are important to direct the water toward the drains as per the water management plan.

Parking decks are costly to build, repair and replace. To have a durable deck, water management is vital. Designing, installing and then testing waterproofing systems are the keys to divert water away from the structural elements. Water is the major cause of concrete deterioration and steel rusting. The waterproofing layer can be placed on the top of the deck system where it’s easy to inspect and repair; however, the layer is not protected from pedestrian and vehicular traffics. Therefore, the preferable approach in parking garages is to use protected waterproofing membrane. As the name implies, the membrane will be protected from the traffic, and that will extend the service life of the deck. Nonetheless, the limited accessibility will make the assembly hard and expensive to maintain. Loose-laid membrane can be applied; however, the most common application of deck membrane is full adhesion.

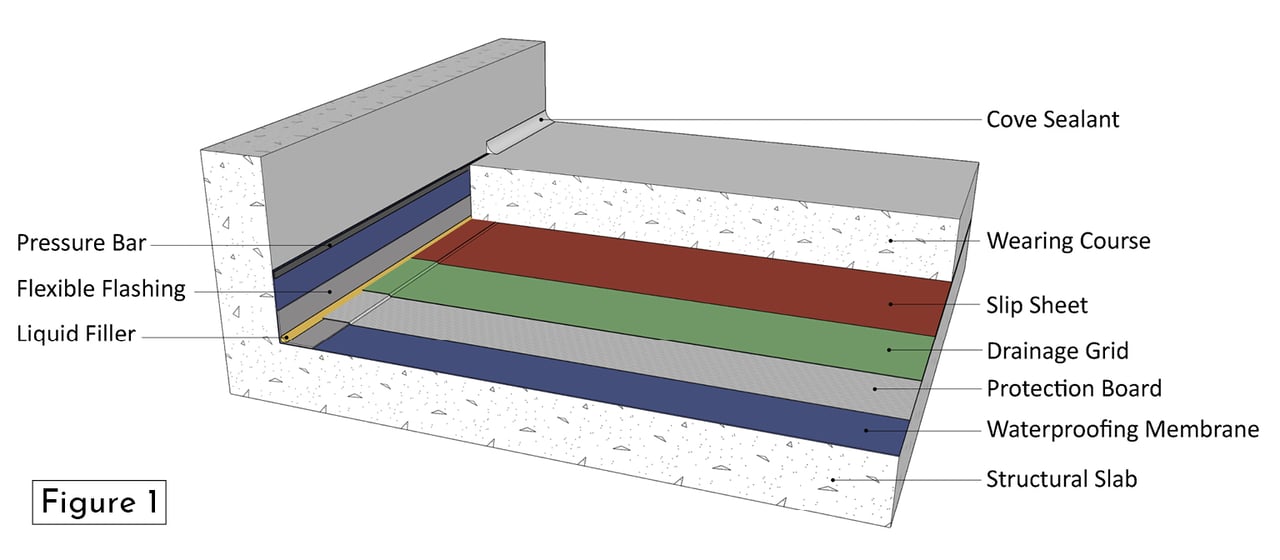

Figure 1: Typical parking deck system

The adhered system can be achieved by cold, hot, or sheet applications. With some challenges with maintaining thicknesses and quality of the installed membrane using cold and hot applications, rolling out premanufactured rubberized-asphalt membrane is the most common application. The sheet membrane has many joints that may leak water if they are not done tightly. Creating a continuous plane throughout the deck - especially around penetrations - is essential for water-tightness. Flashing and pressure bars are used to maintain membrane continuity at terminations. Cracks plus expansion and construction joints in decks require special attention and considerations. The structural behavior of the floor slab, including deflection values and locations, affects the performance of the waterproofing system.

The typical parking deck comprises a waterproofing membrane adhered onto the top of structural slab, drainage grid and wearing course (Figure 1). This assembly works like a rain-screen exterior wall as most of the water trenches over the wearing surface while some water, which finds its way onto the waterproofing membrane, would move towards drains through the drainage grid. Therefore, the topping acts as a membrane protector and water shedding layer – just like siding on walls. Other layers can be added, such as protection boards, insulation and slip sheets to improve the overall performance and durability.

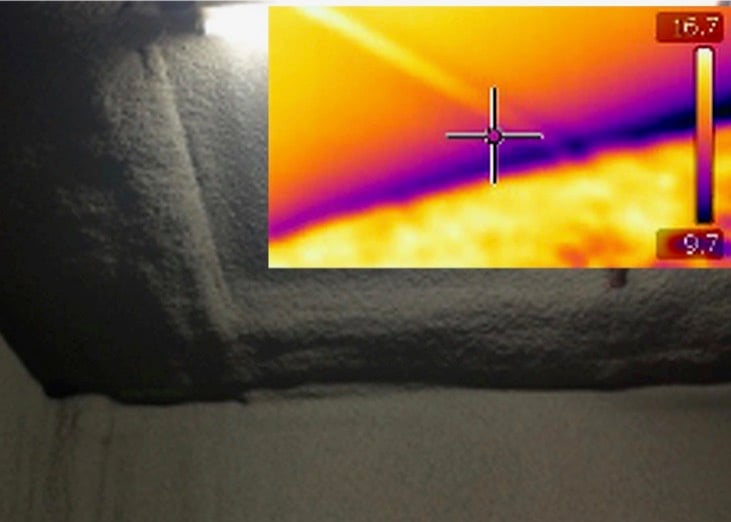

Photo 1: Closed-cell foam insulation on bottom surface of concrete slab - Inset photo: Thermographic scan showing the cold surface in blue due to the lack of exterior insulation

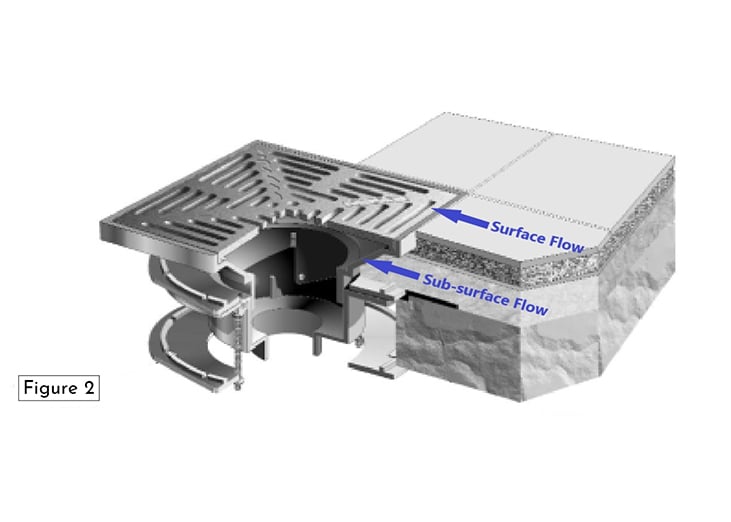

Figure 2: Two-stage drain

An insulation layer within a deck assembly is crucial when it separates two spaces with a wide difference in temperature. That case can exist between a parking floor and air-conditioned/heated living space. Similarly, the lack of insulation (thermal barrier) below a plaza deck and above heated parking space in cold climate can cause condensation issues on the exposed bottom surface of the concrete deck (Photo 1). In contrast to a parking deck that separates two parking floors, a plaza deck is a supported slab that provides green-scape and tree planters in addition to pedestrian vehicle loads over an occupied space.

Unlike fully shielded buildings, parking garages are open to the elements; therefore, concrete surfaces are more prone to deterioration, such as spalling, scaling, cracking and delamination. Parking structures are also subjected to dynamic loading conditions and destructive chemical attacks from de-icing materials in addition to mechanical abrasions from cleaning and snow-removing equipment. Functional maintenance and repair programs are very important to save the structure. In general, a full comprehensive condition review must be conducted by a structural engineer with experience in concrete restoration repair and waterproofing technology every five years or when there are signs of structural and performance issues.

Keeping water drained away from the deck will increase its service life as sitting water rapidly deteriorates the deck components, such as waterproofing membrane and concrete slab. Also, water within the assembly causes extra damage by posing freezing and thawing cycles in cold climates. Maintaining a minimum slope of 2% at the topping (for surface flow) and at deck slab (for sub-surface flow) is essential to direct water towards the highly recommended double-tired drains (Figure 2). Considerations should be given to the effects of structural deflections and building settlements on the magnitudes of slope.

Photo 2: Flood test

Photo 3: Inflatable drain plugs

Photo 4: High-voltage ELD testing

The installation quality of waterproofing membrane is as important as the selection and design of the waterproofing system, as the integrity and continuity of the membrane are paramount to the performance and durability of parking deck systems. Hiring a third-party reviewer to inspect installation and test the system can be very beneficial – especially before adding additional layers and the wearing course. Visual reviews, as part of the quality control program, should be conducted frequently. Testing can be employed as a quality assurance measure.

Flood testing using ASTM D5957-98 “Standard Guide for Flood Testing Horizontal Waterproofing Installations” is a good method to verify the continuity of waterproofing membrane (Photo 2). This test suits parking decks since they have mostly a slope of no greater than 2% (1/4” per ft.) with waterproofing membrane that can be liquid-applied, adhered or loose-laid sheets. Testing is performed for a minimum of 24 hours and maximum of 72 hours when rainfall is not expected. If a failure happens, the tested floor will be drained, and the breach will be mended; then, the retest will be performed using the same conditions. Preparation work is required including installing containment assemblies and plugging the drains with inflatable devices (Photo 3) consisting of a rubber ball, draw chain and ring, and other standard plumbing fixtures.

As an alternative to flood testing, utilizing Electric Leak Detection (ELD) to test the integrity of a waterproofing membrane can be safe, fast, accurate and economical (Photo 4). ASTM D7877-14 “Standard Guide for Electronic Methods for Detecting and Locating Leaks in Waterproof Membranes” describes standard procedures for using electrical-conductance-measurement methods to locate leaks in waterproof membranes.

High-Voltage ELD is getting more popular over the Low-Voltage ELD, because the latter needs wet membrane and cannot test vertical surfaces. An insulation layer under the membrane and having drains can cause misreading of results. Those limitations can be overcome by applying some methods that some would consider unpractical, such as installing electrically conductive primer or lightweight wire-grid under the membrane. Also, some waterproofing membranes such as Butyl and EPDM (Ethylene Propylene Diene Monomer) behave as conductors; therefore, ELD cannot be conducted on them.

Parking decks are harmfully affected by wear, abrasion, aggressive chemical agents, damaging environmental agents, extreme temperature variations, rough use, salt and water intrusions; therefore, they require comprehensive maintenance programs. Ignoring a small water leakage into the assembly may lead to serious and costly structural deficiencies and to catastrophic failures in extreme cases. Preventive measures would increase the service life of parking structures and reduce disruptive and expensive repair. Parking Facility Maintenance Manual, a publication by National Parking Association is a great guide to extend the lifespan of parking garages through site-specific maintenance and repairs.

Amir Hassan, M.Sc., P.Eng., P.E.

Building Science Manager, EXP

Amir Hassan has more than 25 years of experience in Building Envelope and Forensic Restoration in the Middle East, Europe and North America. He has worked on very complex projects for both existing buildings (including historical and heritage buildings) and new construction. His Building Science knowledge includes work with structural glass, curtain wall design and evaluation, frameless and skylight systems, structural assessment, property condition assessment, building enclosure commissioning, roofing and waterproofing systems, weather-tightness, energy modeling, thermal performance, and thermography. Amir has a Bachelor of Science degree in Civil Engineering, and a Master of Science degree in Façade Engineering. He is a frequent speaker and author on roofing and building envelope topics. He’s the current president of Alberta Building Envelope Council North (ABECN). Amir also holds the role of Subject Matter Expert in the field of Building Science with the Association of Professional Engineers and Geoscientists of Alberta (APEGA). He can be reached at: amir.hassan@exp.com - https://www.exp.com

More In The News

Subscribe Today!

Stay-in-the-know and subscribe to our blog today!