Hobby Airport Plans for the Future

Big changes are on the way to William P. Hobby Airport in Houston, Texas. Southwest Airlines, who operates the majority of Hobby’s 22 gates, has plans to build an international facility at the airport to begin serving destinations in Mexico and the Caribbean in 2015. But, before Southwest’s proposal was accepted by Houston City Council in May, 2012, the Houston Airport System approved a renovation plan several years earlier that included new features and improvements to better serve Hobby’s nine million passengers.

Chamberlin was chosen for the building envelope scope of the renovation work by general contractor, Clark Construction. One reason Chamberlin was chosen for the project is their extensive experience with aviation facilities. Chamberlin has been involved with various roofing and waterproofing projects at different airports throughout Texas continuously for the last 30 years. Along with Clark and Wiss, Janney, Elstner Associates (WJE), Chamberlin spent many hours coming up with a complex execution plan for work that would be taking place at Hobby over the course of two years.

Chamberlin was chosen for the building envelope scope of the renovation work by general contractor, Clark Construction. One reason Chamberlin was chosen for the project is their extensive experience with aviation facilities. Chamberlin has been involved with various roofing and waterproofing projects at different airports throughout Texas continuously for the last 30 years. Along with Clark and Wiss, Janney, Elstner Associates (WJE), Chamberlin spent many hours coming up with a complex execution plan for work that would be taking place at Hobby over the course of two years.

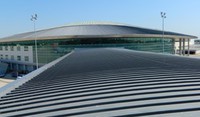

Considering the structure is over 50 years old and has not had a major upgrade in two decades, renovation was essential in order to maintain the reliability of the exterior building envelope. Chamberlin’s roofing scope of work included replacing the modified bituminous roofing system and flashings on the roofs above the main terminal. Additionally, the metal panel roof and skylight systems above the concourse and terminal security area required rework partially due to damage from Hurricane Ike. All panels, flashing and gutter systems were removed. Then, new underlayment was placed over the substrate to prepare for the roof panel and gutter system re-installation.

All roofing work was performed at the fully occupied facility adjacent to secure airport operations. The Chamberlin roofing and sheet metal team led by Project Manager, Marty Hensley, General Roofing Superintendent, Miguel Pecina, General Sheet Metal Superintendent, Ernest Castillo and Sheet Metal Foreman, Jon Jameton, worked to keep disruptions at a minimum. Some work was organized to take place at night in order to safely hoist an on-site metal roll forming machine to fabricate and install 175-foot long panels over the 13,000 square foot pilot’s lounge.

All roofing work was performed at the fully occupied facility adjacent to secure airport operations. The Chamberlin roofing and sheet metal team led by Project Manager, Marty Hensley, General Roofing Superintendent, Miguel Pecina, General Sheet Metal Superintendent, Ernest Castillo and Sheet Metal Foreman, Jon Jameton, worked to keep disruptions at a minimum. Some work was organized to take place at night in order to safely hoist an on-site metal roll forming machine to fabricate and install 175-foot long panels over the 13,000 square foot pilot’s lounge.

“Miguel, Ernest and their team went above and beyond to tackle this challenging project,” said Hensley, “they worked closely with the Clark and WJE groups to produce successful mock-ups of details for the many transitions in the sheet metal roofing system and proactively solve potential issues.”

Due to the nature of the project and consistent winds, materials could not be stored on the roof. They had to be kept in confined areas on the ground away from the work area. Although mobilizing supplies to the roof took a bit more time than usual, it was crucial to ensure a safe work environment and protect the aircraft.

Due to the nature of the project and consistent winds, materials could not be stored on the roof. They had to be kept in confined areas on the ground away from the work area. Although mobilizing supplies to the roof took a bit more time than usual, it was crucial to ensure a safe work environment and protect the aircraft.

“All activities required strict protection for employees and aircraft directly adjacent to the work areas,” said Clark Construction Senior Project Manager, Jason Brooks. “Chamberlin provided creative ways to prevent any material from leaving the roof, even in the event of possible mishandling.”

Working on a fully operational airport facility presents many challenges not faced in conventional construction. For the U-ramp passenger drop-off roadway and waterproofing replacement portion of the project, it was critic al to plan all activities with preventing impacts to the airport and its travelers as the highest priority. The roadway replacement required diversion of vehicular traffic through the garage and maintaining at least three of the four entrances for public access, so there was no way to avoid having public access immediately adjacent to work areas. Due to the nature of the work creating dust, debris, and noise from demolition operations, Chamberlin Waterproofing Superintendent, Mike Hicks had to utilize crews on both the day and night shifts so they could work quickly and avoid traveler discomfort.

al to plan all activities with preventing impacts to the airport and its travelers as the highest priority. The roadway replacement required diversion of vehicular traffic through the garage and maintaining at least three of the four entrances for public access, so there was no way to avoid having public access immediately adjacent to work areas. Due to the nature of the work creating dust, debris, and noise from demolition operations, Chamberlin Waterproofing Superintendent, Mike Hicks had to utilize crews on both the day and night shifts so they could work quickly and avoid traveler discomfort.

“Mike Hicks and his waterproofing team did an excellent job of meeting Clark’s expectations and worked days, nights and weekends if necessary to meet and sometimes beat the scheduled key milestone dates,” said Jonathan Winkles, waterproofing senior project manager for Chamberlin.

The demolition of the existing upper level roadway occurred down to the structural slab and included removal of the existing waterproofing system. Once the substrate was properly prepared, a high strength polymer modified concrete was poured and formed to create slope to the new drains. Upon acceptance of the prepared surface by the manufacturer, Chamberlin began the installation of the cold fluid-applied hybrid waterproofing system. The specialized system was water tested before the final roadway topping slab was poured back into place. Chamberlin finished off the waterproofing portion of work with expansion joint assemblies, joint sealants, metal flashing and deck coating.

“In high risk areas, Chamberlin will often go above and beyond what is indicated. We have found no leaks in any of the completed areas, which is a testament to their workmanship,” said Brooks. “Chamberlin has built a strong reputation on providing a quality product installation.”

“In high risk areas, Chamberlin will often go above and beyond what is indicated. We have found no leaks in any of the completed areas, which is a testament to their workmanship,” said Brooks. “Chamberlin has built a strong reputation on providing a quality product installation.”

After the upper level roadway and building envelope renovation is complete, Southwest Airlines and the Houston Airport System will move forward with their plans to add an international terminal and Federal Inspections Service facility at Hobby beginning in the spring of 2013. By 2015 Hobby International Airport will be a reality with five gates and approximately 12 international flights daily.

Subscribe Today!

Stay-in-the-know and subscribe to our blog today!